MAP25-E: The Ultimate Tray Sealing Solution for Small and Medium-Sized Food Producers

MAP25-E (Extended) Model:

- Seals 4 microwave dinner trays (8.7”x 6.7”) in one cycle.

- Optimized to accommodate different dimensions based on the customer’s specific requirements.

- Ideal for small and medium-sized food producers.

- Achieve increased production while maintaining the highest standards of quality, and with fewer hassles.

The MAP25-E is an innovative packaging machine designed to meet the needs of small and medium-sized food producers. Optimized for multiple tray sizes, this model offers flexibility and customization based on specific customer requirements. With its advanced technology and efficient performance, the MAP25-E extended version helps businesses achieve increased production while maintaining the highest standards of quality.

Features and Benefits:

- Extended Tray Size Capability: The MAP25-E Extended accommodates more trays per sealing cycle than its competitors. It can also accommodate larger trays, providing versatility for a wide range of food products and packaging needs.

- Customizable Design: The machine can be tailored to fit specific customer requirements, ensuring seamless integration into existing production lines.

- High-Speed Operation: The MAP25-E Extended operates at an impressive speed, enabling businesses to meet increasing production demands while maintaining product quality.

- Automated Processes: Advanced automation minimizes manual intervention, reducing labor costs and increasing overall efficiency.

- Optimized Control: The machine incorporates rigorous process control measures, ensuring that each packaged product meets the desired standards.

- Durability and Reliability: Constructed from robust materials and components, the MAP25-E Extended offers long-lasting performance and minimal downtime.

- User-Friendly Interface: The intuitive user interface allows operators to easily set up, operate, and monitor the machine, minimizing training time.

Increased Production and Efficiency:

The MAP25-E Extended is engineered to enhance production capabilities and streamline workflow. Its high-speed operation and automated processes enable businesses to package more products in less time, resulting in increased output and improved productivity.

Quality Assurance:

With its advanced technology and stringent quality control measures, the MAP25-E Extended ensures the highest standards of product quality. The machine’s precise sealing and gas flushing capabilities maintain the freshness, flavor, and nutritional value of packaged foods.

Customization and Flexibility:

The MAP25-E Extended offers unmatched customization options, allowing businesses to tailor the machine to their specific requirements. From tray size adjustments to customized packaging formats, the machine adapts to meet unique production needs.

Conclusion:

The MAP25-E Extended is an indispensable tool for small and medium-sized food producers looking to optimize their packaging operations. Its extended tray size capability, customizable design, high-speed operation, automated processes, quality control, durability, and user-friendly interface make it an ideal solution for businesses seeking increased production, efficiency, and product quality.

Introducing the APACK MAP-25E Semi-Automatic Tray Sealer: Efficiency and Versatility for Modified Atmosphere Packaging

Are you looking to elevate your packaging process with a machine that combines efficiency, flexibility, and advanced technology? Look no further than the APACK MAP-25E Semi-Automatic Tray Sealer. This innovative machine is designed to streamline your packaging operations, ensuring your products are presented attractively and well-protected.

Key Features and Benefits:

- Modified Atmosphere Packaging (MAP) Excellence: The MAP-25E excels in vacuum drawing and gas flushing in a single operation, sealing trays with top film while under pressure. This process extends the shelf life of your products by reducing oxygen levels and inhibiting the growth of spoilage microorganisms.

- Customization and Flexibility: APACK understands that one size doesn’t fit all. That’s why the MAP-25E is built to various dimensions and can accommodate different tray sizes (up to 100mm) with various plates. This adaptability ensures a perfect fit for your specific packaging needs.

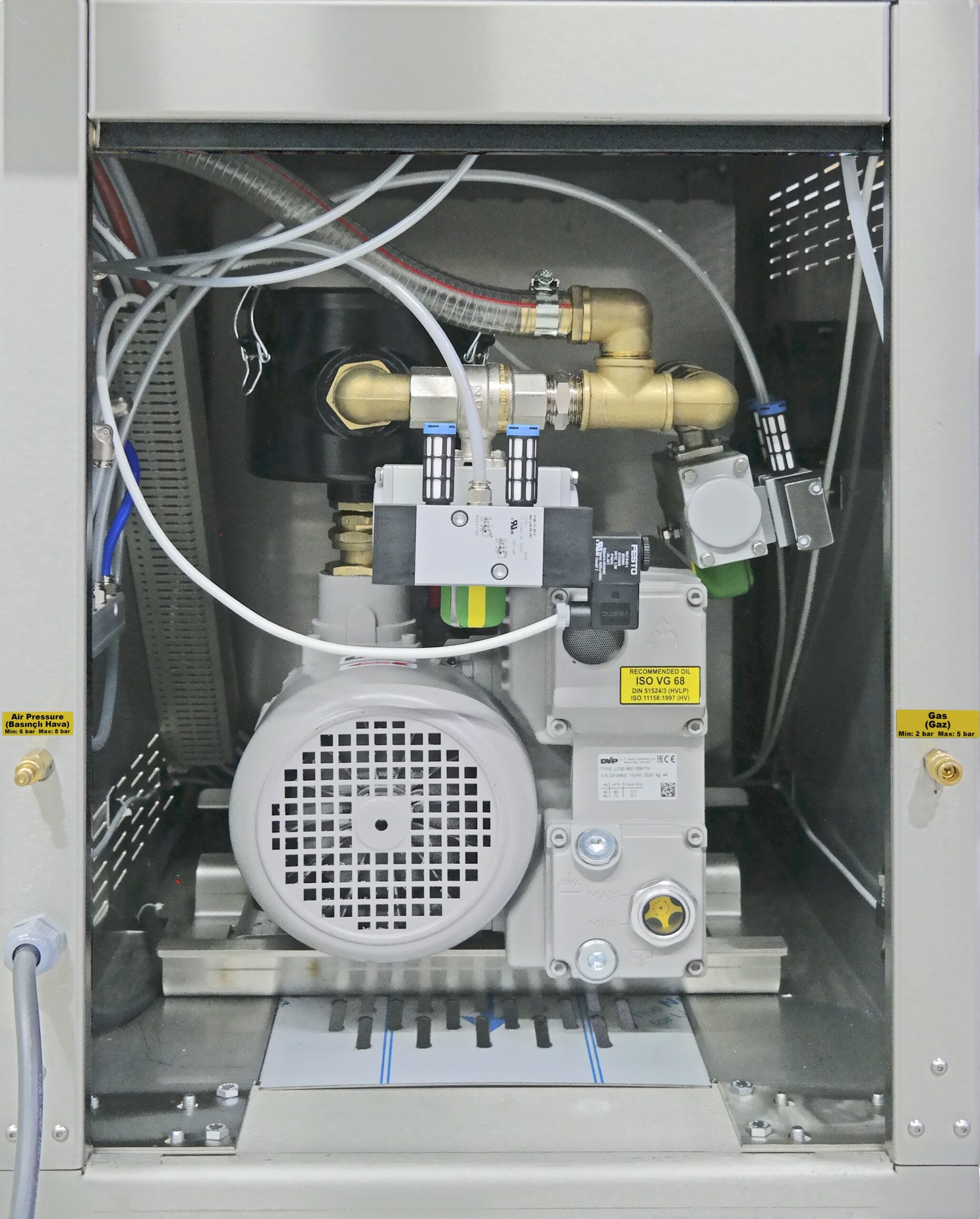

- Increased Production Speeds: Equipped with larger vacuum pumps, the MAP-25E optimizes production speeds, allowing you to meet the demands of your business efficiently.

- User-Friendly Operation: Designed with simplicity in mind, the MAP-25E requires only one operator, reducing labor costs and streamlining your workflow. (Note: The MAP25DS Double Station Model requires two operators.)

- Zero2 Oxygene Software: This innovative software progressively removes oxygen from the package, further enhancing the preservation of your products and maintaining their quality.

- Remote Access Capability: The MAP-25E is compatible with a remote access option, enabling you to control its electrical, electronic, and mechanical systems via the internet. This feature provides added convenience and control over your packaging process.

- Ideal for Various Industries: The MAP-25E is a versatile solution for a wide range of industries, including snack foods, confectionery, fresh-cut vegetables, and more. Whether you’re packaging vegetarian or non-vegetarian products, this machine can handle your needs.

- Built to Last: APACK has a 20-year legacy of manufacturing high-quality machinery. The MAP-25E is built with precision and durability, ensuring reliable performance for years to come.

- Backed by Expertise: APACK’s reputation for exceptional service and support is unmatched. With a team of experienced professionals, you can count on APACK for assistance with demos, market tests, training, emergency support, and more.

Why Choose the APACK MAP-25E?

The APACK MAP-25E is more than just a tray sealer; it’s a comprehensive packaging solution that offers:

- Enhanced Product Quality and Shelf Life: MAP technology preserves the freshness, appearance, and taste of your products, reducing waste and increasing customer satisfaction.

- Improved Efficiency and Productivity: With its user-friendly operation and customizable features, the MAP-25E streamlines your packaging process, saving you time and money.

- Versatility and Adaptability: The MAP-25E can handle a wide range of products and packaging requirements, making it a valuable asset for any business.

- Peace of Mind: APACK’s commitment to quality, service, and support ensures that you have a reliable partner for all your packaging needs.

Upgrade your packaging process with the APACK MAP-25E Semi-Automatic Tray Sealer and experience the difference that quality and innovation can make.

APACK builds this model in various dimensions, on top of that providing the flexibility to change the standard tray sizes (up to 100mm.) with different plates and holding the larger vacuum pumps for increased production speeds.

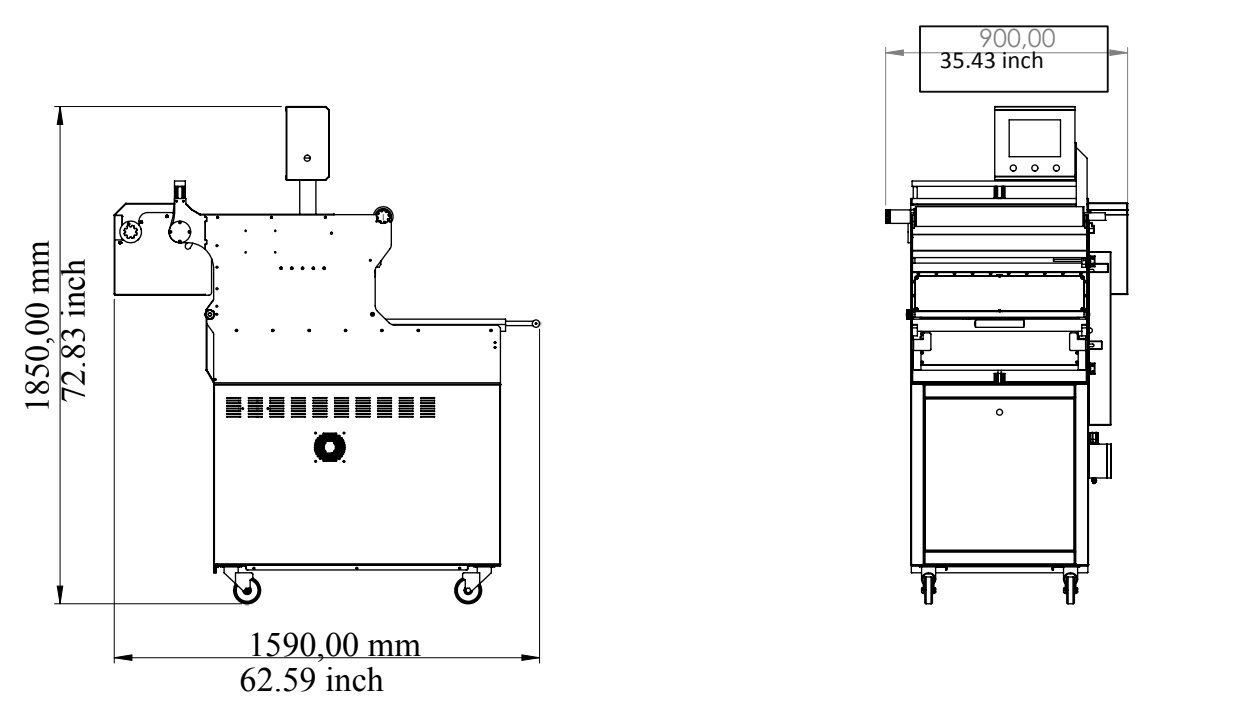

MAP25E (Extended) model is designed to use big size trays. APACK manufactures this model to different dimensions for customers demands and needs

We have built our reputation as the best service company in the industry based on demo, market test, service, training, emergency support, professional expertise and experience and of course the quality/reliability of our machines range.

We have been manufacturing and designing our machinery, down to the smallest component, using our own expertise and knowhow since 2008. The machines we have manufactured comply with international standards and certification.

MAP-25E is innovative designed by APACK Team for vacuum drawing and gas flushing in one go and sealing tray with top film while tray is under pressure.

MAP-25E is compatible for remote access option to control the MAP-25E’s electric – electronic and mechanic system via internet.

Only one operator required (Except MAP25DS -Double Station- Model requires two operators).

MAP-25E tray sealer hermetically seals special plastic containers using a flexible film. While sealing, a good level of vacuum can be reached inside the container as well as the insertion of different types of inert gases.

MAP-25E can handle also the entire production of most small and medium businesses in vegetarian or non vegetarian snack food, confectionery and fresh cut vegetables.

MAP-25E has own Zero2 Oxygene software. With this software, MAP-25E take all Oxygen progressively out from the package. Semiautomatic MAP-25E thermal sealer unit is manufactured by high quality craft workmanship.

20 years of experiance to be exact, lies behind the APACK brand. We provide machinery and services to hundereds of companies in Turkey and abroad. We work in cooperation with over 800 scientists and technicians worldwide to innovate our machinery and solutions.

Your product is supposed to be presented as attractively and well-protected as possible.