EcoSEAL series are packaging lines that can meet all your packaging needs with fully automatic systems. Operation starts from tray placing, covers all stages such as filling, weighing, sorting, sealing, labeling, collecting and stacking the product.

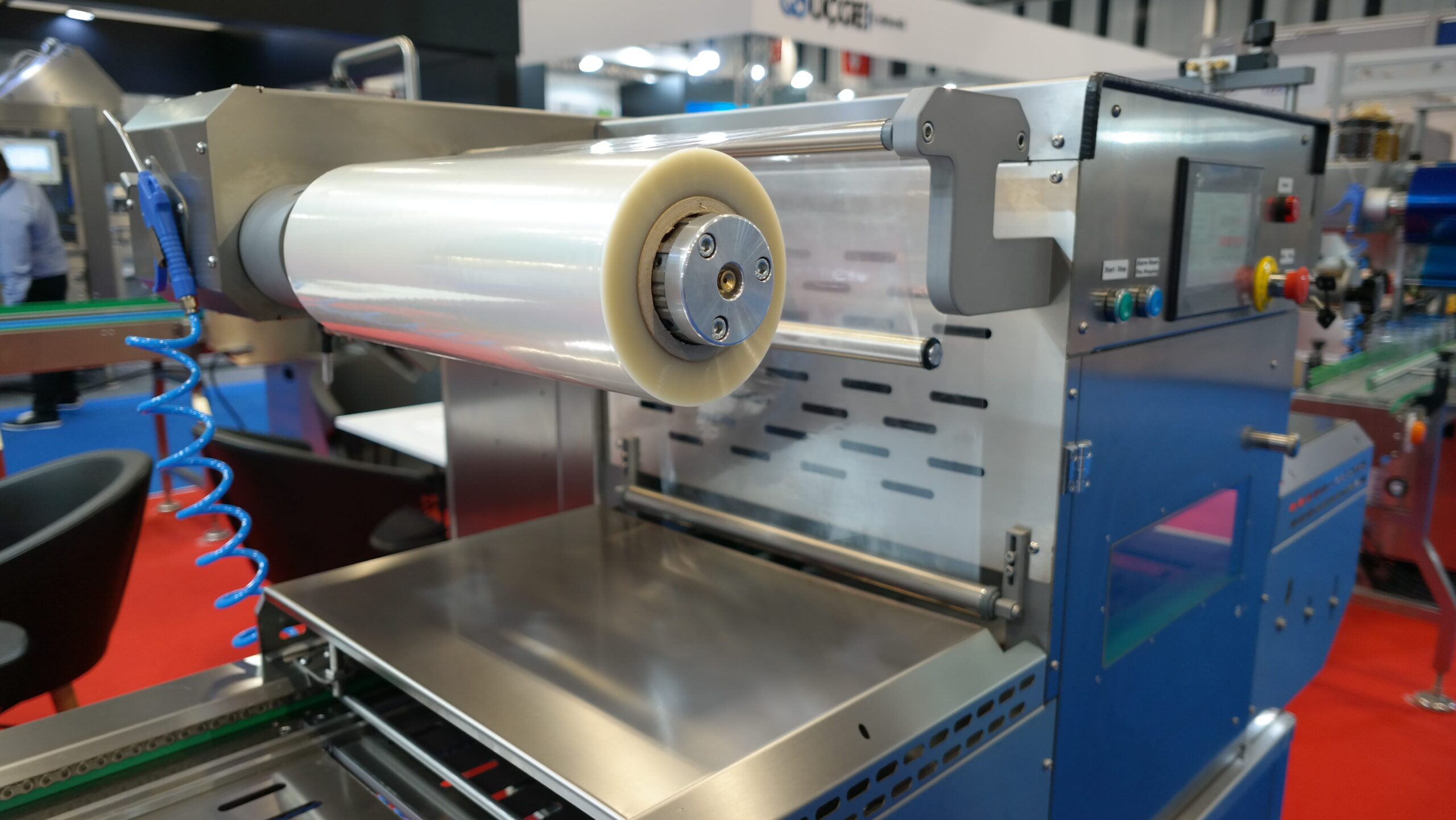

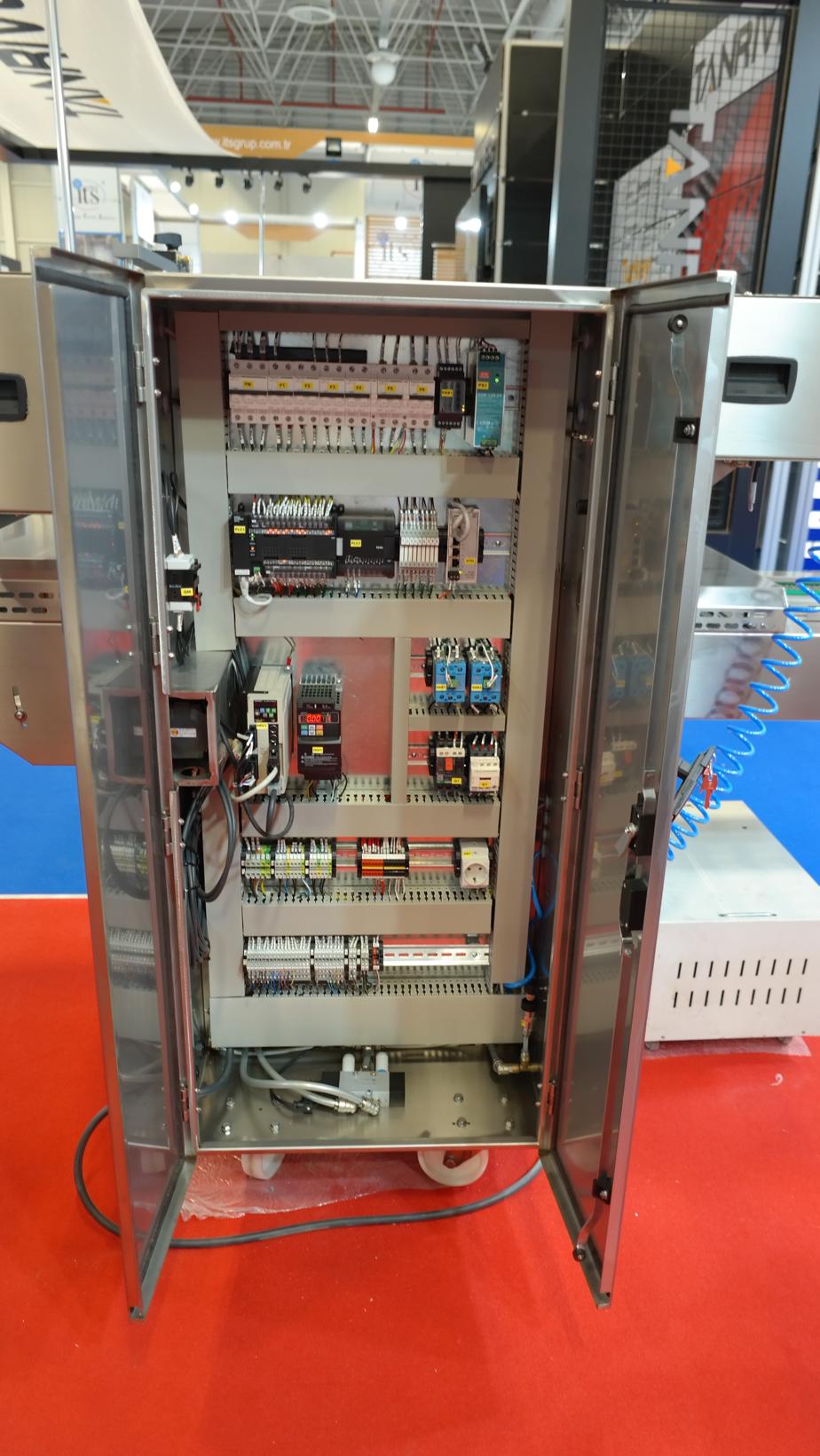

The body of our machines is completely made of AISI 304 stainless steel. Molds are processed from 5000 and 7000 series aluminum on our own CNC machines. Moving belts and moving elements are made of hygienic material. Mechanical, electrical, electronic and pneumatic parts are selected from the highest quality brands. The machine is very easy to use, maintain and clean.

It is suitable for the use of single or multi-compartment trays.

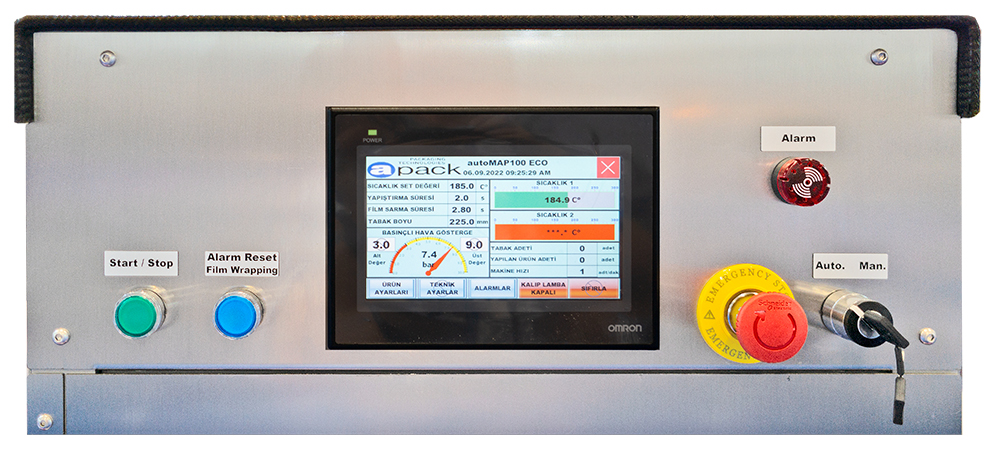

Thanks to its colored touch screen, every step of the packaging process can be easily controlled. With a large number of PLC control circuits, all stages of production and possible error messages are instantly displayed on the screen. All processes can be adjusted in accordance with all kinds of trays and films. With 99 program memories, it is possible to easily switch to different production models. Mold changing, film rolls changing applications are much simplified. In this way, all kinds of interventions can be easily performed by the company staff.

The PLC unit, which performs all kinds of monitoring and control of the production line, immediately warns about possible errors, misuse and installation malfunctions and protects the system.

Our EcoSEAL series machines are designed considering the working conditions in your country and are manufactured by APACK. Our EcoSEAL series machines are designed for long-term uninterrupted production.

Introducing the EcoSEAL Tray Sealer: Efficient, Versatile, and Customizable Packaging Solution

Are you looking for a reliable and efficient tray sealing solution that can adapt to your specific production needs? Look no further than the EcoSEAL series from APACK, a leading manufacturer of packaging machines.

Designed for Versatility and Efficiency

The EcoSEAL series is a range of fully automatic tray sealing machines designed to streamline your packaging process. Whether you’re in the food, pharmaceutical, or consumer goods industry, these machines can handle a wide variety of products and tray types. With its advanced features and customizable options, the EcoSEAL series can be tailored to meet your unique production requirements.

Key Features and Benefits:

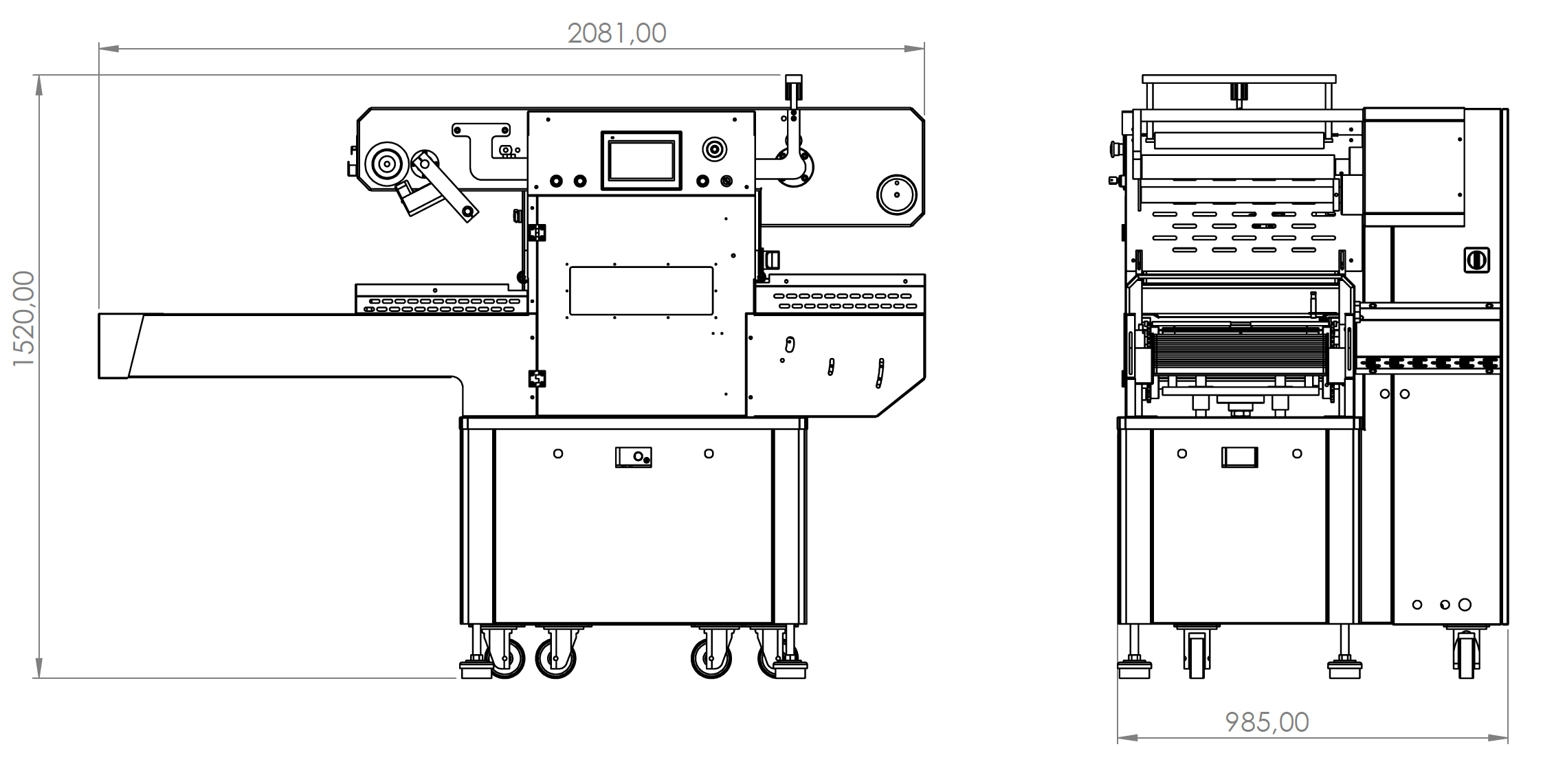

- Compact and Space-Saving: The EcoSEAL 100Mini model is specifically designed for businesses with limited production space and budget constraints. It offers all the essential features of a fully automatic machine in a compact footprint, making it ideal for small to medium-sized operations.

- Fully Customizable: The EcoSEAL series can be fully customized to integrate seamlessly with your existing production line. From tray size and shape to sealing options and labeling requirements, APACK can design a solution that fits your specific needs.

- User-Friendly Interface: The EcoSEAL machines feature a colored touch screen interface that provides easy control over every step of the packaging process. The intuitive interface allows operators to quickly adjust settings, monitor production, and troubleshoot any issues.

- Advanced PLC Control: The machines are equipped with a powerful PLC control system that monitors and controls all aspects of the production line. The system provides real-time feedback on production status, error messages, and maintenance alerts, ensuring optimal performance and minimizing downtime.

- High-Quality Construction: The EcoSEAL machines are built to last, with a stainless steel body and high-quality components from leading brands. The machines are also designed for easy maintenance and cleaning, reducing downtime and improving overall efficiency.

- Comprehensive Packaging Solutions: The EcoSEAL series can handle a wide range of packaging tasks, including tray denesting, filling, sealing, labeling, and sorting. This comprehensive functionality eliminates the need for multiple machines, saving space and improving productivity.

- Energy-Efficient and Environmentally Friendly: The EcoSEAL machines are designed with energy efficiency in mind, helping you reduce your operating costs and minimize your environmental impact.

Why Choose the EcoSEAL Series?

- Improved Efficiency: The EcoSEAL series automates the tray sealing process, reducing labor costs and improving productivity.

- Enhanced Product Quality: The machines ensure consistent and reliable seals, protecting your products from contamination and extending their shelf life.

- Increased Flexibility: The customizable options allow you to adapt the machines to your changing production needs.

- Reduced Downtime: The high-quality construction and advanced PLC control system minimize maintenance requirements and downtime.

- Cost-Effective Solution: The EcoSEAL series offers a cost-effective packaging solution that can improve your bottom line.

Upgrade Your Packaging Process with EcoSEAL

If you’re looking for a reliable, efficient, and customizable tray sealing solution, the EcoSEAL series from APACK is the perfect choice. Contact us today to learn more about how EcoSEAL can benefit your business.