Apack autoMAP (100, 200)

Accommodates larger package sizes than autoMAP100-Mini

Higher volume output than autoMAP100-Mini

Machine dimensions can be customized to fit your packaging and space requirements

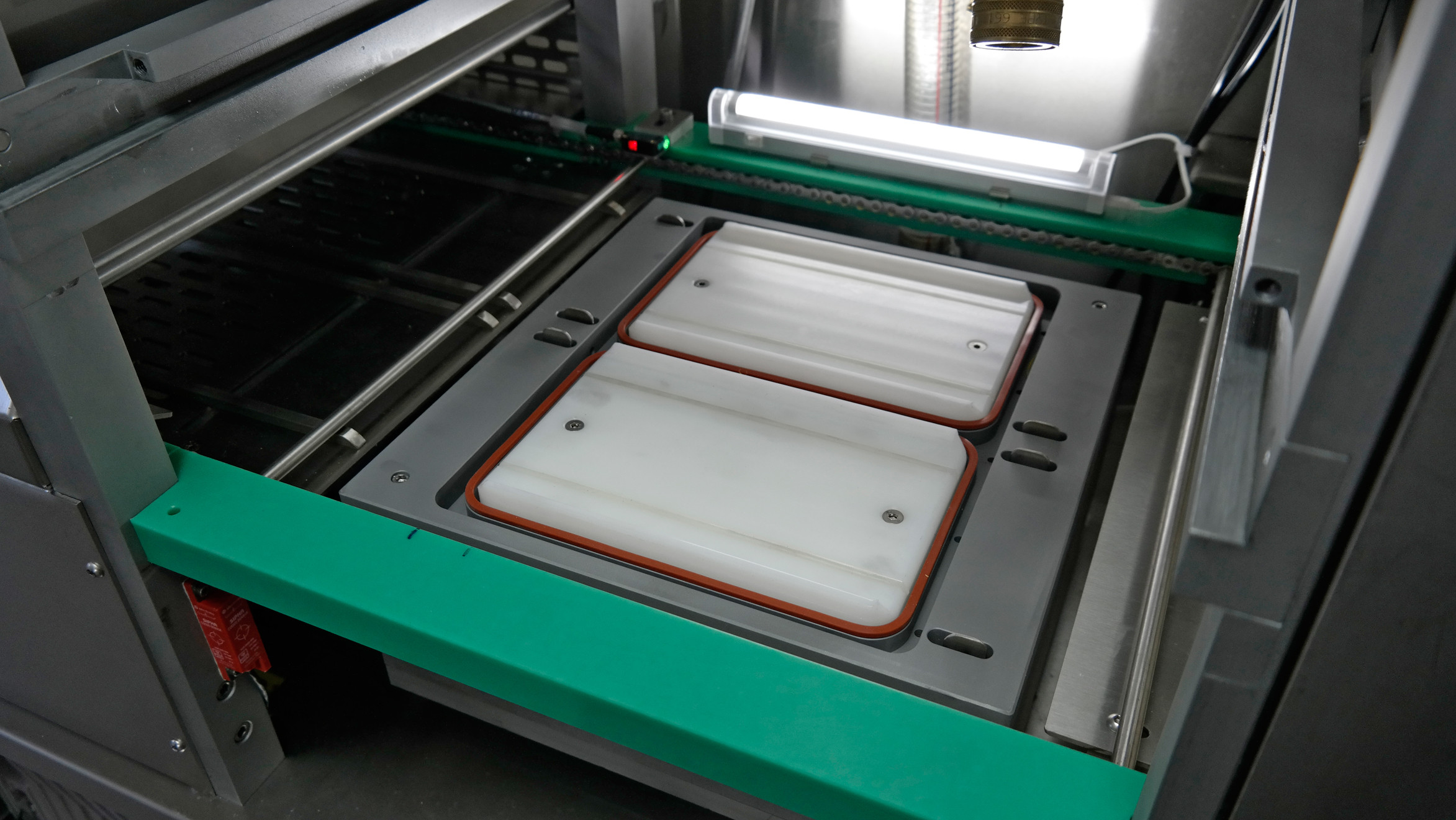

APACK autoMAP100 and autoMAP200 series machines provide fully automatic tray sealing and MAP (Modified Atmosphere Packaging) solutions for food production facilities of all different sizes and output volumes.

All of the machines in the APACK autoMAP100 and autoMAP200 series are designed to be customizable, dependable, efficient, and easy to use. Decades of research, development, and industry experience allow APACK to offer you the perfect MAP solution to fit your facility’s unique requirements.

All-in-One, Fully-Automated MAP Solution

Each of the autoMAP100 and autoMAP200 series machines has the ability to carry out fully-automated MAP process and continuous operation

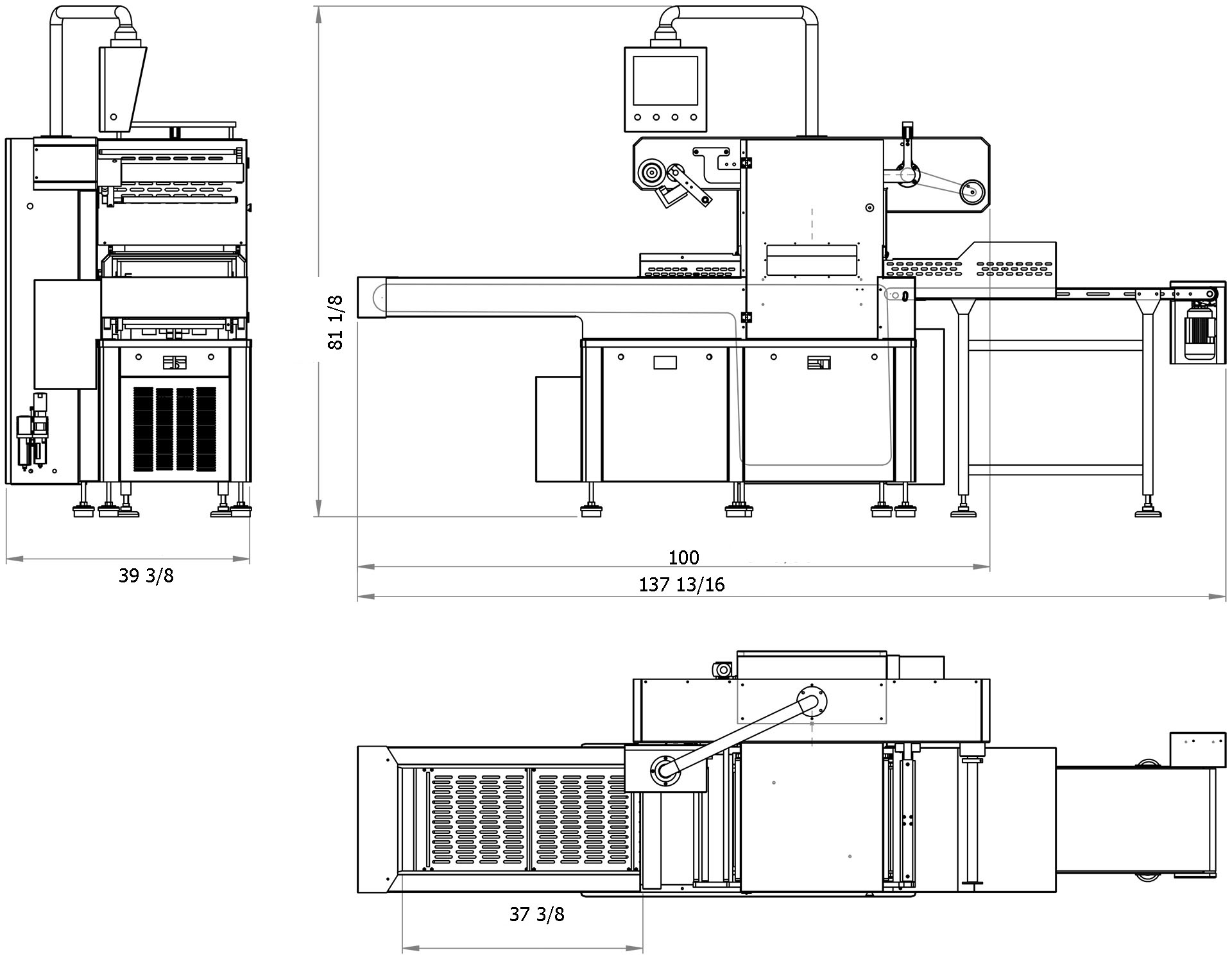

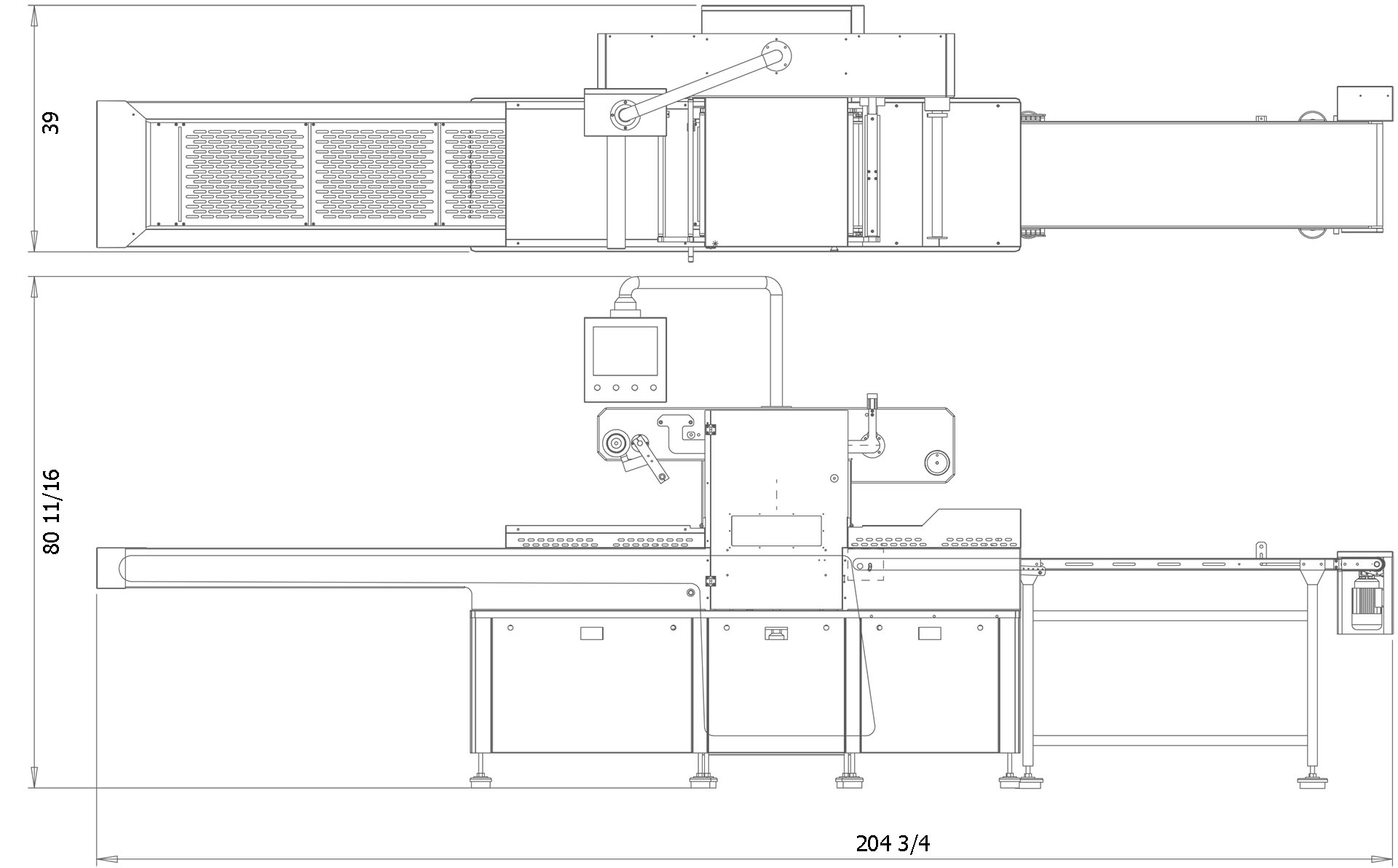

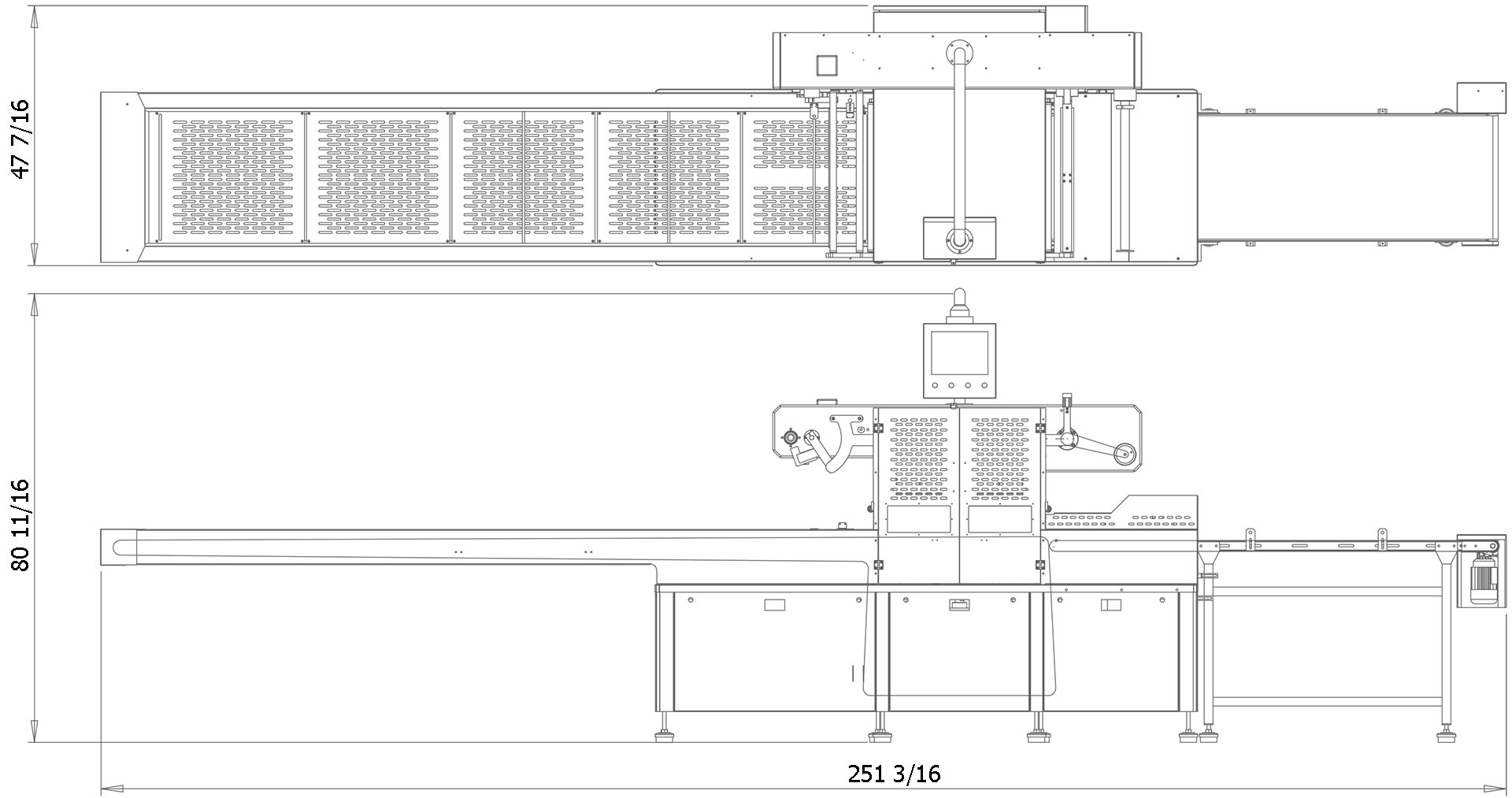

| automap100-Mini | autoMAP100-E | autoMAP200-E | |

|---|---|---|---|

| Vacuum Pump | 105-205 m³/h | 105-205 m³/h | 105-205 m³/h |

| Compressed Air Pressure | 90 psi constant and dry | 90 psi constant and dry | 90 psi constant and dry |

| Gas Pressure | 30 – 90 psi | 30 – 90 psi | 30 – 90 psi |

| Control Panel | Touchscreen | Touchscreen | Touchscreen |

| Dimensions (WxLxH) | 35.43″ x 131.88 x 80.70″ | 38.97″ x 207.7″ x 80.70″ | 46.45 x 251.1″ x 80.70″ |

| Loading Area Length | 31.49″ | 5′-10′ | 5′-10′ |

| Weight | 1323-1763 lbs. | 1763-2645 | 3086-3858 |

| Max Film Width | 15.74″ | 15.74″ | 23.62″ |

| Max Cut-off Length | 18.11″ | 18.11″ | 25.19″ |

Efficiency and Ease of Use

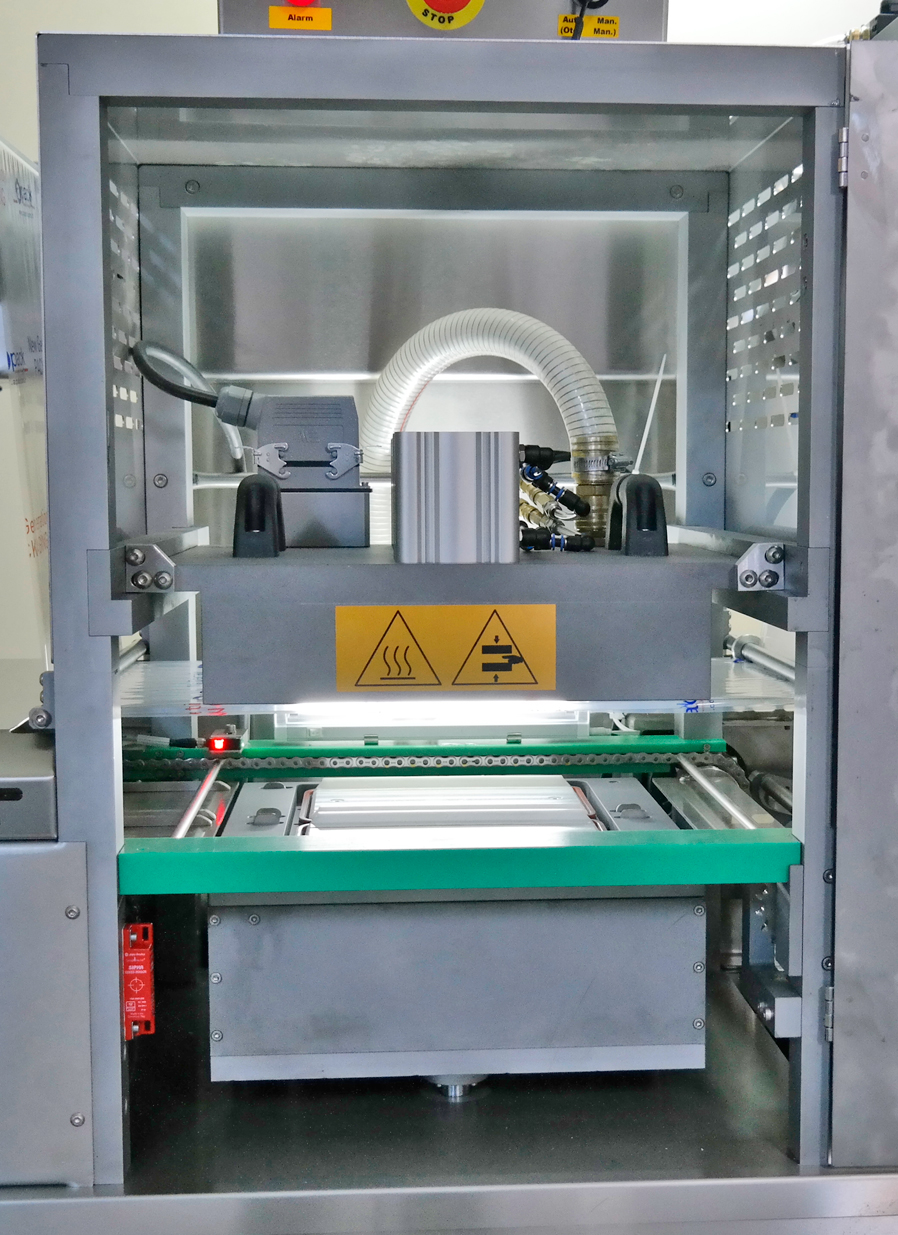

Simple, intuitive touch-screen panel makes for fast and easy operation and reduces user error

Multi-program memory allows for quick transition between different packaging types

Maintain a safe, sterile food processing environment: stainless steel body, easily removable panels, and hygienically designed conveyor belts and moving parts make frequent cleaning easier

Versatility

All operation parameters can be adjusted to various tray and film sizes

Vacuum packing function for easy hermetic sealing of liquids, sauces, dressings, and hot-filled products

Many customization features are available to fit your facility’s specific needs

Dependability

PLC control circuits constantly monitor operation to protect equipment against possible faults, misuse, or malfunction

Invicta’s industry-leading customer service and support means you’ll avoid costly interruptions in production

Designed and manufactured by APACK – over 20 years at the leading edge of food packaging

Designed to operate 24/7 under normal conditions with no interruptions

Different Models to Fit Your Needs

The APACK autoMAP100 and autoMAP200 series include four different models, so you can choose one that addresses your needs perfectly.

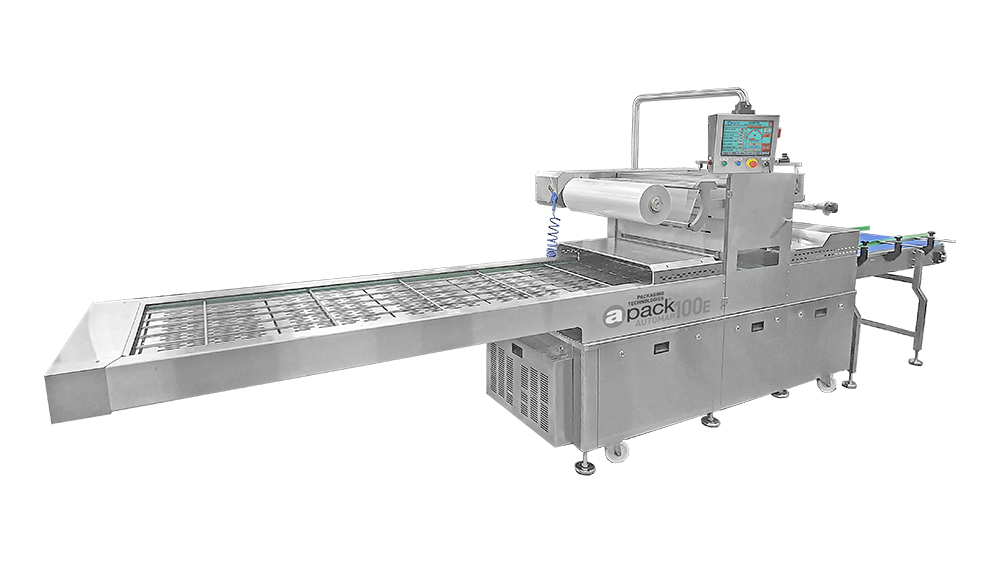

autoMAP100-Mini

-Compact, economical design allows the autoMAP100-Mini to fit in processing facilities where space is at a premium

-Performs all of the same processes as the larger sized models

-Perfect for lower-output facilities working on a budget

-Full automation features and online diagnostic access available upon request

Innovative, Flexible, Professional and Comprehensive solutions for your exact needs…APACK manufactures its packaging machines with their unique designs, down to the smallest parts in its own facilities that complies with the international standards and certification. autoMAP100 series packaging lines will meet all your packaging needs with fully automated systems.The production lines include stages from feeding the trays, filling the product, weighing, sorting, MAP sealing, labeling, collection, and storage.

In autoMAP 100E; volume and dimensions of the standard tray mold structure of AutoMap 100 are expanded to accommodate larger packages. Machine dimensions can be customizable based on clients packaging preferences and needs.

If you need large packages than you need autoMAP100E Fully Automatic MAP Packaging lines that includes vacuum, gas flush options.

Stainless-steel body and hygienically designed conveyor belts and moving parts allow for cleaning and maintenance without any hassle. It also suitable for using single and multiple trays.

Accomplish with excellence by Functional Control System

By means of touch-screen panel, every step of the packaging process can be controlled easily. The automation unit with PLC control circuits, monitors and controls processing line provides immediate alerts on possible faults, misuse, and equipment malfunctions, thus protects the systems. Multiple program memory makes it easy to switch to different package types. All procedures can be adjusted according to various trays and films sizes.

Innovative, Flexible, Professional and Comprehensive solutions for your exact needs…APACK manufactures its packaging machines with their unique designs, down to the smallest parts in its own facilities that complies with the international standards and certification.

autoMAP100Mini provides great convenience in terms of both budget and size.With its compact design, fits the most processing spaces while carrying all the feature of autoMAP 100 series. Full automation add-ons such as online-access, fully automatic filling, plate feeding, weighing, labeling etc . can be applied to all autoMAP series.

If you have small production areas than you need autoMAP100Mini Fully Automatic MAP Packaging lines that includes vacuum, gas flush options.

Stainless-steel body and hygienically designed conveyor belts and moving parts allow for cleaning and maintenance without any hassle. It also suitable for using single and multiple trays.

Our autoMAP100Mini serie mapping machines provides quick service and cleaning facilities by easy-removable side covers . All frames and intermediate elements were manufactured with ISI304 stainless steel.

We build the autoMAP100Mini unit with using polished construction materal for safe and hygiene in VDE-CE standards . All machine series have EMERGENCY STOP function.

Mould can change very quickly and easily. Automatic tray dispanser, automatic product scaling and filling unit, labeling and barcoding units, product collectors and boxing units can be added.

All machine can command via over very useful PLC touchscreen. LCD Graphic Display with touchscreen is very easy to use. Multilingual programmed control panel can turn to the desired direction in VDU norms. Adjustable up to 99 different process programs. The minimum and maximum temperature values can be monitored simultaneously on the touchscreen. The unit’s working order and possible errors, error logs are displayed on the control display. All the settings and features of the machine functions can be controlled from the touchscreen. If necessary, the work settings can be avoided by locking for the potential user faults. Counting products, hours of operation, cycles, production process, errors, functions reports can show in any time on the control panel.

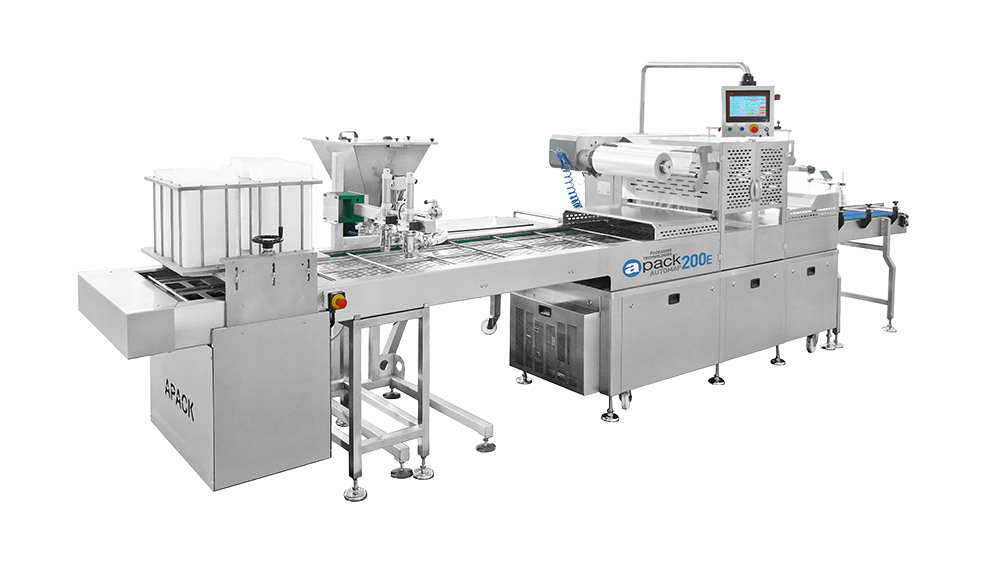

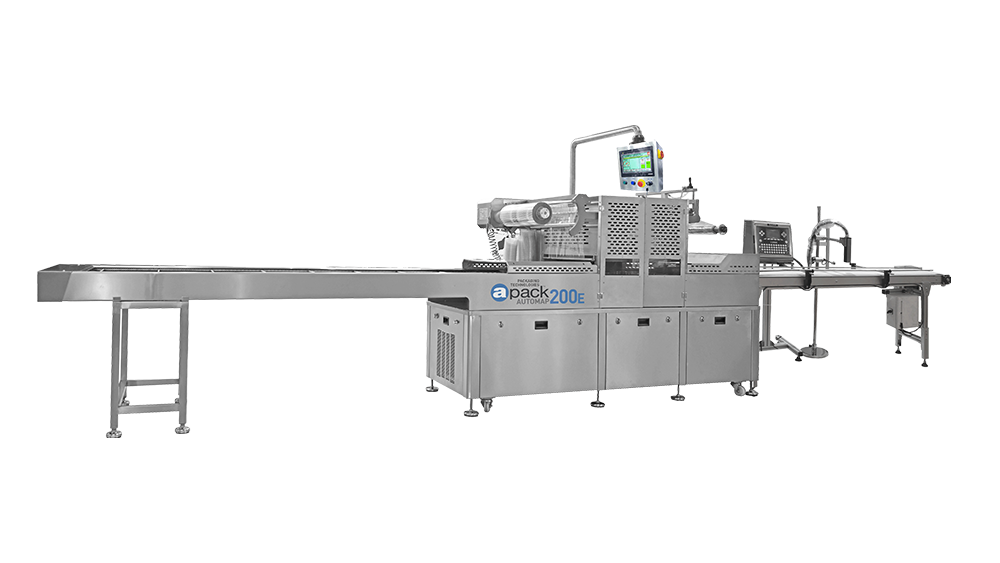

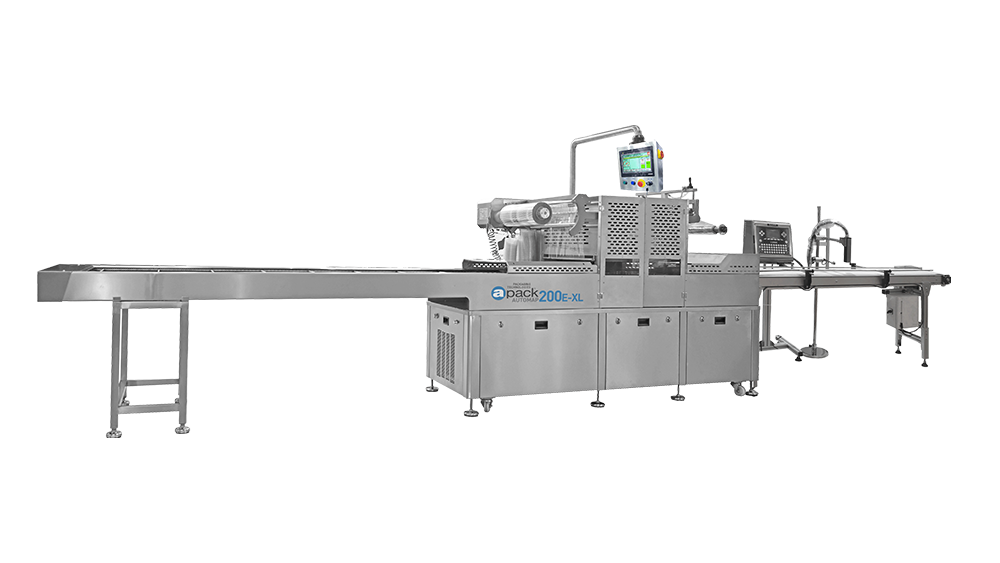

autoMAP200-E (Extended)

-Accommodates larger tray sizes than autoMAP100-E

-2-row production line for double the output of autoMAP100-E

-Design and dimensions of autoMAP200-E is optimized for larger package sizes

-If you need high capasity MAP packaging automation, this is what you search for. autoMAP200E series full automatic MAP tray sealer line gives you a hand more than a standard Mapping machine. On basis, there is not so much difference between autoMAP100 to autoMAP200 models. autoMAP100 has one row production line but autoMAP200 has 2 rows line. Therefore the capasity doubled. The machine dimension is longer than autoMAP100. The pump is bigger, mould technique is different. autoMAP200E is suitable for high volume production. The line may contains tray dispanser, autofilling unit, scaling, mapping, labeling, barcoding, collecting etc. units depends on your demands.

-autoMAP200E model developed for big and heavy products. The machine body and mold dimensions are extended what you needs. autoMAP200 redesigned for your demands depens on your product and production types.

-Stainless-steel body and hygienically designed conveyor belts and moving parts allow for cleaning and maintenance without any hassle. It also suitable for using single and multiple trays.

-Accomplish with excellence by Functional Control System

-By means of touch-screen panel, every step of the packaging process can be controlled easily. The automation unit with PLC control circuits, monitors and controls processing line provides immediate alerts on possible faults, misuse, and equipment malfunctions, thus protects the systems. Multiple program memory makes it easy to switch to different package types. All procedures can be adjusted according to various trays and films sizes.

-APACK autoMAP100 and autoMAP200 Series: Revolutionizing Tray Sealing and Modified Atmosphere Packaging

In the competitive food production industry, optimizing your packaging process is essential for maintaining product quality, extending shelf life, and maximizing efficiency. The APACK autoMAP100 and autoMAP200 series of fully automated tray sealing machines offer a comprehensive solution to meet the diverse needs of food production facilities, regardless of size or output volume.

Unmatched Efficiency and Productivity

The autoMAP series is engineered to streamline your packaging operations, integrating seamlessly from tray feeding to final storage. By automating the entire process, these machines minimize manual handling and reduce the risk of human error, resulting in significantly increased throughput and improved overall efficiency. Whether you’re a small-scale operation or a large production facility, the autoMAP series can be tailored to your specific requirements, ensuring optimal performance and productivity.

Key Features and Benefits

All-in-One, Fully Automated MAP Solution: The autoMAP series handles the entire Modified Atmosphere Packaging (MAP) process, including tray denesting, filling, sealing, labeling, and sorting. This comprehensive approach eliminates the need for multiple machines and reduces labor costs, while ensuring a consistent and high-quality packaging process.

Efficiency and Ease of Use: The intuitive touch-screen panel simplifies operation and minimizes user error, while multi-program memory allows for quick transitions between different packaging types. The stainless steel body, easily removable panels, and hygienically designed components facilitate cleaning and maintenance, ensuring a safe and sterile food processing environment.

Versatility: The autoMAP series accommodates various tray and film sizes, and offers a vacuum packing function for liquids, sauces, dressings, and hot-filled products. With a range of customization options available, you can create a tailored solution that perfectly fits your facility’s unique needs.

Dependability: PLC control circuits continuously monitor operation to prevent faults and malfunctions, ensuring uninterrupted production. Backed by Invicta’s industry-leading customer service and support, you can minimize downtime and avoid costly disruptions. Designed and manufactured by APACK, a company with over 20 years of experience in food packaging, the autoMAP series is built to operate 24/7 under normal conditions, providing long-term reliability and maximizing your investment.

Different Models to Fit Your Needs

The APACK autoMAP100 and autoMAP200 series include four distinct models, each designed to address specific production requirements:

autoMAP100-Mini: This compact and economical model is ideal for smaller facilities with limited space. It offers the same functionality as larger models, making it a cost-effective solution for lower-output operations. Full automation features and online diagnostic access are available upon request.

autoMAP100-E (Extended) and autoMAP200-E (Extended): These models accommodate larger tray sizes and offer higher output volumes, making them suitable for growing businesses and larger production facilities.

autoMAP200: The autoMAP200 boasts a 2-row production line, doubling the output of the autoMAP100-E and optimizing efficiency for larger package sizes.

The APACK Advantage

Choosing the APACK autoMAP series means investing in a packaging solution that delivers:

Increased Production Capacity: Meet growing customer demands and expand your business with the high-speed, efficient autoMAP machines.

Improved Product Quality and Safety: Minimize contamination risks and ensure consistent quality with automated processes and hygienic design.

Extended Shelf Life: Preserve product freshness and reduce waste with advanced MAP technology.

Enhanced Operational Efficiency: Streamline your packaging process, reduce labor costs, and improve overall productivity.

Reduced Environmental Impact: Optimize resource utilization and minimize waste with efficient and sustainable packaging solutions.

Experience the Future of Packaging

The APACK autoMAP100 autoMAp100 mini and autoMAP200 series represent the cutting edge of tray sealing and MAP technology. With their unmatched efficiency, versatility, and dependability, these machines can revolutionize your packaging process and help your business thrive in a competitive marketplace. Contact Triton International today to learn more about how the autoMAP series can transform your operations and elevate your packaging capabilities.

TYPES OF PACKAGING

One team approach

One team approach

Triton International Enterprises specializes in providing high-quality food packaging solutions tailored to meet the diverse needs of the food industry. Our extensive product range includes food packaging films, bags, trays, and advanced packaging machinery, all designed to ensure the freshness and safety of your products.